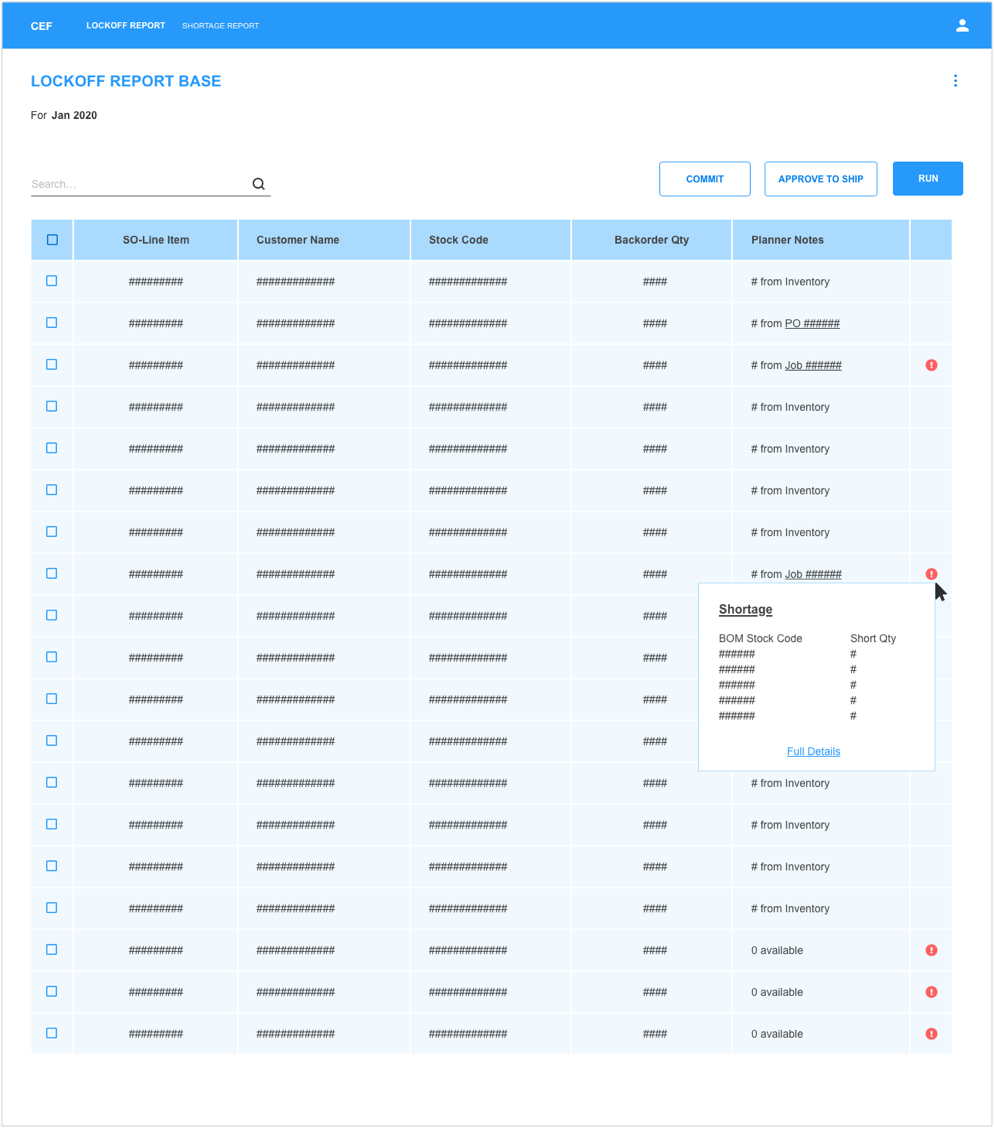

Shortage Planning in Manufacturing

The client is a full service manufacturing company in an engineering-heavy and specialized industry. Their planners do resource planning almost completely manually by taking notes of shortages in excel. This is an incredibly tedious and time-consuming process which can take them up to 3 days to complete. By then, the data is likely no longer accurate, and they may have to start again.

The Process

The first phase of this project was spent deep-diving into the available data to understand what we could potentially build. During that time, we also conducted multiple discovery sessions with the planners to learn what they were looking for, what data they used, and how they got what they needed with the current system. Based on these discovery sessions, we constructed a workflow that helped to consolidate our and stakeholders’ understanding of the workload involved with shortage planning. We then designed three concepts that helped the planners achieve their same desired outcome and tested them for which fit their model of shortage reporting the best.

Throughout the development phase of this project, we continued testing the prototypes with the planners and other stakeholders to ensure we were meeting both user and the business needs

*For the privacy of my client, I have refrained from sharing the full details & deliverables.